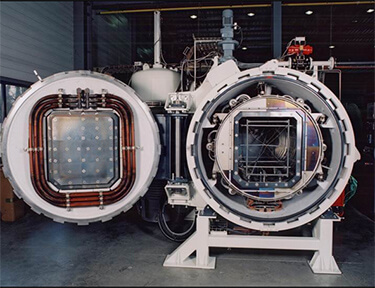

Mold heat treatment is an important process to ensure mold performance. It has a direct impact on the following properties of the mold. Mold manufacturing accuracy: uneven and incomplete structural transformation and excessive residual stress caused by heat treatment cause the mold to deform during processing, assembly and use of the mold after heat treatment, thereby reducing the accuracy of the mold and even scrapping it.

59 Apr 08,2020In the process of die casting production, due to factors such as pressure shock and insufficient clamping force, the occurrence of burrs in zinc alloy die castings is inevitable. In recent years, with the increasing quality requirements of die castings, the requirements on burrs have become stricter, and the methods of deburring have also emerged endlessly. The deburring process is also the most annoying thing. Here are some simple ways to deburr.

166 Apr 01,2020

The key elements of die-casting technology include equipment, molds and processes. Various quality problems will occur during the die-casting production process. In addition to the instability of the system caused by equipment performance and quality, there are some accessories (such as melting cups, punches, etc. and process parameters accuracy and auxiliary materials may cause hidden dangers to quality.

46 Mar 27,2020Most of the sanitary ware products after die-casting molding or machining also need to be polished and polished or after a variety of surface treatment addition and for a good finished product.

60 Mar 19,2020

The automatic control of die-casting temperature controller is an indispensable means in modern die casting technology. What is the function of die casting hot die machine in the temperature control of die casting?

76 Mar 13,2020Macro-porosity is a common internal defect of aluminum alloy die-castings; it often occurs whenthe product has a thick wall or is prone to hot spots.Generally speaking, as long as the macro-porosity does not affect the performance of the pr

117 Feb 28,2020

The quality of the die-casting mold directly affects the quality of the die-casting parts. After the die-casting mold is manufactured and delivered to the die-casting factory, as a die-casting factory, it is difficult for us to change the p...

75 Feb 21,2020

“More than a month and a half into the outbreak of a new coronavirus in China, the country's economy is still largely in lockdown mode, stalling a global manufacturing powerhouse at the heart of nearly every industrial supply chain. A...

49 Feb 21,2020

In addition to the main failure modes of die-casting molds under the influence of molten metal erosion and thermal stress on the surface, thermal fatigue damage is also caused. In the actual production process, the micro structure and electrical discharge machining of die materials will also cause cracking failures of die-casting molds.

86 Feb 07,2020

Optimization of Process Structure for Machining Die Castings Abstract: In the design of die casting mould, more consideration is given to the curability of the mould itself, such as runner, overflow, temperature, ejection, etc. However, if...

71 Jan 15,2020

For the production of die-casting molds, mold steel is generally used, and then processed through special production. No matter how perfect the mold is, there are limits to its use.

253 Dec 06,2019

In die casting mold manufacturing, the most common form of mold damage is cracks and cracks. Stress is the main cause of mold damage.

85 Dec 06,2019

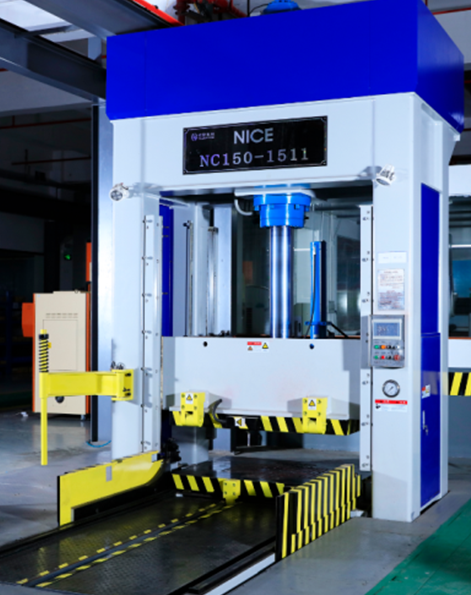

Aluminum die-casting is a kind of pressure-casting parts. It is a die-casting mechanical die-casting machine with a casting mold installed.

58 Dec 06,2019

The correct use of aluminum alloy die-casting molds can not only extend the life of aluminum alloy die-casting molds, but also improve the quality of the products.

39 Dec 06,2019

Process of aluminum alloy die casting. Aluminum alloy die-casting is a type of die-casting part. It is a die-casting mechanical die-casting machine equipped with a casting mold.

96 Dec 06,2019

First, the dimensional accuracy of die-casting molds ensures standard maintenance. Some of the most common examples of pressure die-casting include the use of cylinder blocks, levers, gears, toy assemblies and other components in almost every industrial sector.

54 Dec 06,2019

Lead-zinc ore processing zinc alloy die-casting system uses zinc alloy lead-zinc production process flow for casting and rolling. This kind of alloy has a low melting point and can be cast into a variety of precise and messy components.

108 Dec 04,2019

Zinc alloy die-casting production does not happen overnight. It takes many steps to complete. First, when users have a new project, they will find a zinc alloy die-casting factory for evaluation and quotation.

41 Dec 04,2019

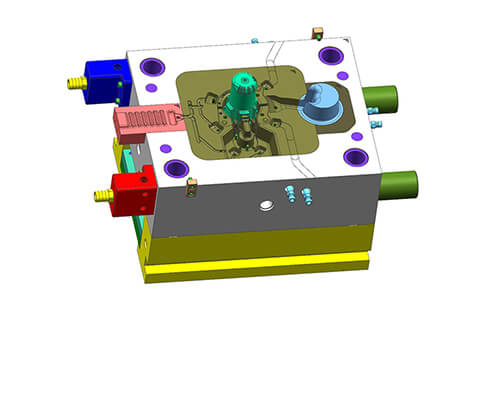

We all know that die-casting is one-piece molding, so the design of die-casting molds is the basic guarantee for good zinc alloy die-casting. So what should be paid attention to during the design of die-casting molds?

38 Dec 04,2019Product Material:AZ91D

Product Size (LxWxH): 277.2x175.87x152.76mm

Product Industry:Auto battery cover

Magnesium die casting

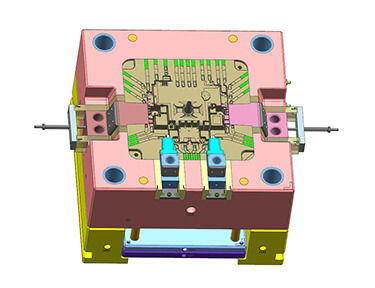

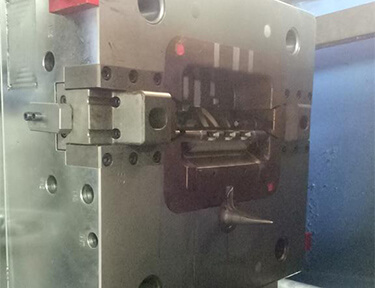

Magnesium die castingProduct Material:Zinc 8#

Product Size (LxWxH): 121.54x47.25x35.13mm

Product Industry:Lamp base

Zinc die casting die-Core side

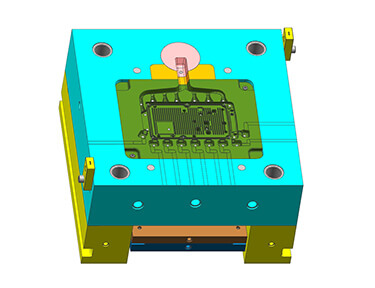

Zinc die casting die-Core sideProduct Material:AL380

Product Size (LxWxH): 173.68x175.17x54.32mm

Product Size (LxWxH): 173.67x175.74x55.62mm

Product Industry:Auto industry ( used for Top cover of auto air conditioning compressor)

Aluminum casting

Aluminum castingEmail: [email protected]

Tel: CHINA TEL: +86 (0)755 8344 0917

The U.S. TEL: +1 615 968 3002

Fax: +86-755-8455 9450

Location:No.311, Chengtou Business Building, Qinglin West Road, Longgang District, Shenzhen, CHINA

Tel