Email: [email protected]

Tel: CHINA TEL: +86 (0)755 8344 0917

The U.S. TEL: +1 615 968 3002

Fax: +86-755-8455 9450

Location:No.311, Chengtou Business Building, Qinglin West Road, Longgang District, Shenzhen, CHINA

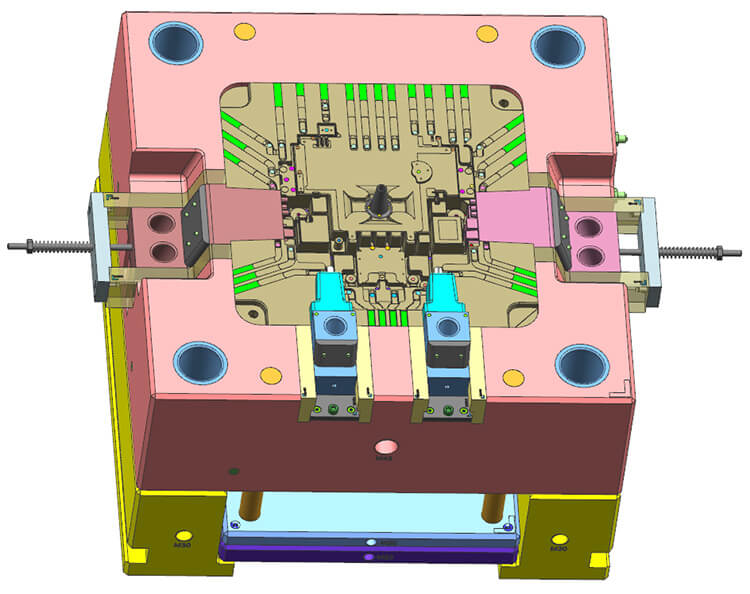

First, the dimensional accuracy of die-casting molds ensures standard maintenance. Some of the most common examples of pressure die-casting include the use of cylinder blocks, levers, gears, toy assemblies and other components in almost every industrial sector. Metal-pressing processes include die-casting alloys with low melting points, including aluminum, zinc, magnesium, Copper, tin, lead, silver, etc.

Secondly, die casting mold processing includes some metal processing industrial production activities. Strict measures must be taken to reduce costs and reduce waste. The entire process of metal casting production was carried out with a minimum amount of waste. Machine tool improvements and suppliers were used to improve alloys. Process itself. Choosing the right alloy material is necessary because each of them offers specific advantages to the finished part.

In short, pressure saves a lot of time and resources in the processing of die casting molds, which leads to huge savings. Automation equipment manufacturing technology, software, and control of travel time can greatly reduce costs. Embracing technological advances Machine tool suppliers can save irreplaceable resources, time and energy. Committed to these changes, the company will be able to achieve more efficient production processes, economic scale, improve competitiveness and solidify its position in the global market.

Camel Die Limited was founded in 2009. 10 years experience in die casting die industry, focusing on aluminum alloy, zinc alloy and magnesium alloy die casting die manufacturing to provide professional and comprehensive solutions. At the same time, it provides design support for die- casting mould and small batch production service.

Tel