With a background of a profound understanding of the requirements of export quality molds to European and North American companies, and the observation of frustration which takes place when overseas purchasers encounter failure from negative experiences working with unprofessional suppliers in the south of China, as well as when quality did not match with pricing, projects being delayed, poor communication in English, lost contracts with suppliers, etc., CAMEL was born. Since 2009, Simon and Leo - as founders who established CAMEL as a professional engineering company in Hong Kong and work place in Shenzhen city - have only one purpose, which is to provide international buyers the best engineering service for export molds without misunderstandings of the standards of mold making, and to offer the best quality and excellent lead time....

Read more +

24 hours on-line service (China/USA teams)...

We fulfill what we promise, Initiative to provide solutions...

Project Engineers oriented in management mode...

Complete internal training system, Professional career planning...

On time delivery rate at 97.14%...

Stable running in die casting and mold life is longer than...

24 hours for quote and DFM, 3 days for 3D mold drawing...

Your reliable partner & Not afraid of challenges...

Good reputation from clients within 10 years...

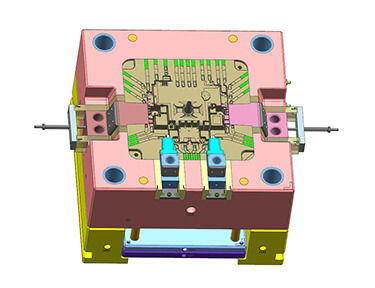

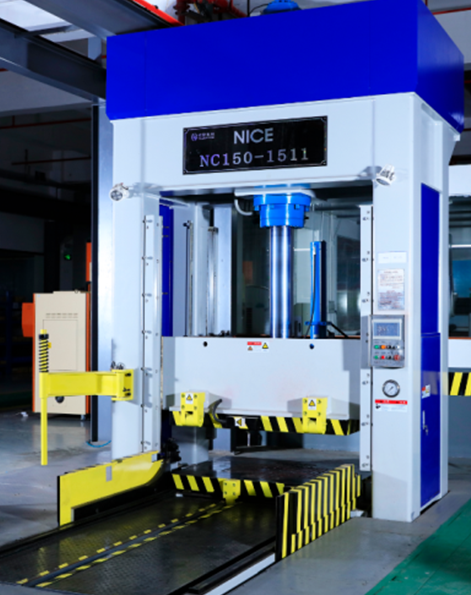

Process of aluminum alloy die casting. Aluminum alloy die-casting is a type of die-casting part. It is a die-casting mechanical die-casting machine equipped with a casting mold.

96 Dec 06,2019

First, the dimensional accuracy of die-casting molds ensures standard maintenance. Some of the most common examples of pressure die-casting include the use of cylinder blocks, levers, gears, toy assemblies and other components in almost every industrial sector.

54 Dec 06,2019

Mold heat treatment is an important process to ensure mold performance. It has a direct impact on the following properties of the mold. Mold manufacturing accuracy: uneven and incomplete structural transformation and excessive residual stress caused by heat treatment cause the mold to deform during processing, assembly and use of the mold after heat treatment, thereby reducing the accuracy of the mold and even scrapping it.

59 Apr 08,2020In the process of die casting production, due to factors such as pressure shock and insufficient clamping force, the occurrence of burrs in zinc alloy die castings is inevitable. In recent years, with the increasing quality requirements of die castings, the requirements on burrs have become stricter, and the methods of deburring have also emerged endlessly. The deburring process is also the most annoying thing. Here are some simple ways to deburr.

166 Apr 01,2020

The key elements of die-casting technology include equipment, molds and processes. Various quality problems will occur during the die-casting production process. In addition to the instability of the system caused by equipment performance and quality, there are some accessories (such as melting cups, punches, etc. and process parameters accuracy and auxiliary materials may cause hidden dangers to quality.

46 Mar 27,2020

Tel